Assembly systems built from extruded aluminum T slot profiles succeed because they adapt to nearly any layout. Their strength comes not only from the profiles themselves but from the hardware designed to grip, anchor, and hold every connection point. Understanding how each piece works reveals why MiniTec Aluminum Framing remains one of the most flexible building platforms for machinery, enclosures, and custom structures.

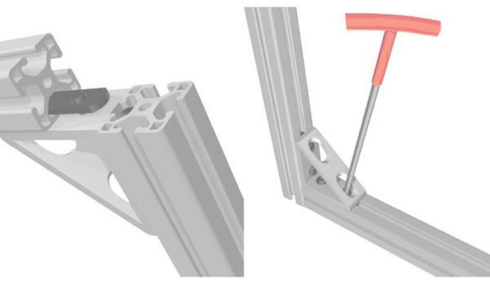

Slide-in T Nuts Lock into Extrusion Slots for Secure Joints

Slide-in T nuts form the foundation of nearly every connection in a T slot extrusion build. These components slide into the channels of MiniTec extruded aluminum framing and rotate or seat themselves to create a threaded anchor point inside the profile. Their design allows strong joints without drilling or permanent modification to the structure.

What makes slide-in T nuts particularly useful is their load distribution. They brace themselves against the inner walls of the T slot, spreading force across the extrusion rather than concentrating it at a single point. This stability supports heavy assemblies while allowing adjustments whenever needed. MiniTec Solutions supplies a wide range of T nut sizes to match differing load requirements.

Corner Brackets Clamp Adjoining Profiles at Right Angles

Corner brackets allow builders to join profiles at clean 90-degree angles. They attach through the T slot using threaded fasteners and create rigid support for frames, machine bases, or enclosure panels. The bracket design ensures square alignment even under repeated vibration or movement.

The convenience of these brackets lies in how easily they reposition. By loosening the connecting fasteners, users can slide the bracket along the extrusion and adjust the structure without rebuilding from scratch. For teams customizing MiniTec Aluminum Framing layouts, these brackets provide both strength and flexible configuration.

Drop-in Anchors Let Fasteners Insert Without Disassembly

Drop-in anchors solve a common problem: adding hardware to an already built assembly. Instead of dismantling sections to insert T nuts, drop-in anchors can be inserted into the T slot at any opening and rotated into position. This feature saves hours of labor during modifications or expansions.

Their locking action ensures they stay seated even when the extrusion is vertical. Because they engage securely inside the channel, builders can attach additional brackets, hinges, or panels with minimal interruption. T slot aluminum extrusion systems benefit greatly from this upgrade-friendly hardware.

Joining Plates Span Between Extrusions to Tie Sections Firm

Joining plates reinforce long spans or connect extrusions that need more surface contact than a basic bracket can provide. These flat plates bolt across profiles, distributing force evenly and reducing flex in frames subjected to lateral loads or repeated stress.

The versatility of these plates supports complex builds such as conveyor frames or modular machine structures. With multiple hole patterns, they adapt to various profile sizes and allow compact, low-profile joints. These plates enhance durability across MiniTec extruded aluminum framing projects.

Threaded Fasteners Tighten Hardware Without Surface Drilling

Threaded fasteners designed for T slot extrusion systems eliminate the need for surface drilling. Instead, they tighten directly into T nuts or anchors housed inside the profile. This design preserves the extrusion’s finish and avoids weakening the frame with unnecessary holes.

These fasteners offer a clean, professional appearance while delivering consistent clamping force. Their compatibility across T slot extrusion hardware makes assembly straightforward for both beginners and experienced builders. MiniTec Solutions provides fasteners that match each extrusion series for proper fit and performance.

End Caps Cover Open Profiles and Hold Slim Connectors

End caps serve two roles: they close off open profile ends for a finished look and protect internal channels from dust or debris. Some caps also include small slots or retention features that allow slim connectors or wiring to pass through.

Beyond aesthetics, end caps prevent accidental snagging and reduce wear on surrounding components. In automated environments, keeping the internal cavity clear helps maintain smooth operation. These small accessories add polish and functionality to any T slot aluminum extrusion project.

Gussets Reinforce Corners Against Twisting or Flexing

Gussets strengthen connections where twisting forces or heavy loads are present. Unlike standard corner brackets, gussets offer broader surface contact and often include multiple fastener points. This design increases stiffness and reduces deflection under pressure.

Industrial frames for conveyors, robotic cells, and equipment guards often rely on gussets to maintain alignment. Their reinforcement capabilities make extruded aluminum T slot systems capable of handling demanding structural applications without shifting over time.

Hinge Hardware Adds Movement Where Door Sections Mount

Hinges enable movement in doors, access panels, or adjustable arms built with T slot extrusion. They attach securely using T nuts or anchors and allow smooth rotation without compromising frame strength. Variations include lift-off hinges, locking hinges, and continuous hinge designs.

These components help builders integrate safety gates, inspection windows, and modular access points into equipment or enclosures. Because hinge hardware attaches within the T groove, installations remain clean and aligned with profile surfaces.

Channel Screws Pull Connectors Tight Inside the T Groove

Channel screws tighten from the outside while pulling internal connectors snugly against the groove. Their angled or specialized heads create mechanical advantage, locking components together with minimal effort. This approach ensures a tight bond between connectors and the extrusion.

The controlled engagement prevents over-tightening, which could damage the profile. For large assemblies or repetitive builds, channel screws speed installation significantly. MiniTec Solutions supports these fastening systems with compatible connectors that match different profile geometries.

Connection hardware defines how flexible and reliable a T slot extrusion system can be. MiniTec Solutions provides high-quality connectors, brackets, fasteners, and accessories that help engineers and builders design strong, adaptable structures that suit both industrial and custom applications.